Statistician Dr. W. Edwards Deming presents the information in his book Out of the Crisis as a tool to be used in order to help with the transformation of the Western/American management style. As he describes it, Japan’s awakening to statistical principles, attention to quality, systems, and better management helped to turn their economy around after WWII by making products of increasingly higher quality and for cheaper prices. This rise by Japan caused trouble for Western and U.S. industry, and in order to halt the decline and change the trend, Deming’s book provides the foundation for an awakening and action to address the crisis. Deming is a firm believer in the effect that management and men have on business and processes, and this book provides thorough explanation in order to help one measure the performance of management as well as provide insight on how things may have been done wrongly. The meat of this book offers Deming’s 14 Points for Management that aim to transform American industry, an outline of diseases and obstacles that stand in the way of such a transformation, comments about quality, and details about common and special causes.

Deming’s 14 Points for Management require adoption and action as a signal from management that they intend to remain in business and want to protect both jobs and investors. These points are lessons for top management, and are widely applicable to many different organizations of varying sizes and industries. The 14 Points for the Transformation of Management are enumerated below:

- Create a constancy of purpose for the improvement of services and products. This first point aims to help management think both long and short term; planning for the future in addition to worrying about problems of today. In order for this to be done, innovation, research, education, and design improvement must be invested in, and top management should work to publish a resolution stating their commitment the purpose and that no jobs will be lost for contributions to productivity and quality.

- Adopt the new philosophy. On all levels, a renewed commitment requires that previously accepted levels of mistakes, defects, poor training, uncommitted management, etc. not be accepted.

- Cease the dependence on mass inspection. Deming says that inspection with the intention to improve quality, is an attempt that is too late. This point asserts that quality comes from improvement of production processes and not from inspection.

- The practice of awarding business based on the price tag alone should be ended. This point illustrates that without adequate quality measurements, business given to the lowest bidder is buying low quality for high cost.

- Constantly and forever improve the system of service and production, beginning with the design stage, and continuing with improvement downstream.

- Institute training in order for management to understand the company, the problems that affect production workers’ production, and the effective use of the abilities of people.

- The adoption and installing of leadership, where management must work on improvement sources.

- Drive out fear, because best performances won’t occur from employees unless they feel secure.

- Break down barriers between staff areas so that problems can be better addressed.

- Eliminate slogans and targets for workers. Eliminate programs promoting zero defects and that target new productivity levels. Such slogans serve only to encourage relationships that are adversarial and counterproductive, due to the fact that productivity and quality levels belong to the system, not to the individual workers. Eliminate management by objective and instead institute leadership.

- Point 11a is to eliminate numerical quotas placed on the work force, and point 11b is to do the same for those in management. Deming states that quotas work to prevent quality and productivity improvements.

- Remove the barriers that work to rob people of their pride of workmanship; mot to treat people like commodities.

- Encourage self-improvement and education for everyone, and the last is to take action to accomplish the intended transformation. The Shewhart cycle is offered as a helpful tool for managers to follow at every step of the fourteen points for improvement, which will also help to find special causes indicated by statistical signs.

- The transformation is a job that belongs to all workers in the organization. The last point is to put everyone to work in order to accomplish the transformation.

For an updated list of Deming’s 14 points, visit: https://www.deming.org/theman/theories/fourteenpoints

The 14 Points offered by Deming provide for a theory of management to address the declining state of Western industries, and functions as a tool to help with the reconstruction of Western Management. Deming provides what he calls the deadly diseases that most Western companies are afflicted with. These deadly diseases include the lacking of a constancy of purpose with the intent to plan service and product that will maintain a market, provide jobs, and keep a company in business, which correlates with point one of the fourteen points. In addition, they include an emphasis on short-term thinking and short-term profits, merit ratings, reviews, and evaluations, job hopping, management by the use of only visible figures, and excessive medical costs. The last enumerated disease is the excessive costs of liability that come from numbers inflated by lawyers who work on contingency fees.

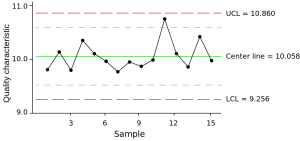

Deming describes quality as a concept that has many faces, with each agent of a product, service, or company having a different definition. He describes the measurement of quality as being the interaction between three different participants; the product itself, the user and how they use, install, and maintain the product, and their expectations as developed by advertising of the product. In order for a company to remain competitive and provide good quality, they must maintain communication with both their users and potential users. Consumer research and sampling can be done with specific procedures, and are important for redesign, and improvement of products for customers. In product design, Deming suggests four steps that deal with designing, making, selling, and testing, then repeating the steps in order to form a helix of improving quality at lower costs.

This book, Out of the Crisis, aims to help those who work in inefficient and poorly ran systems to see what problems and errors they may be falling victim to. Deming’s 14 Points aim to provide a new way for managers to think about their roles and the ways in which their companies function, and such thinking and attention given to the information posed in the 14 Points can help managers to take more in-depth steps to address problems. Deming states that his plan may take a while, 5 years or more, but reframing Western management is necessary if companies are to compete with the cost and quality of more efficient systems like Japan. This book was published in the 1980’s, but with the competitive nature of international business, its principles are still sound for laying the foundation for effective management and leadership.

This article is an adapted sample from a synopsis paper on Out of the Crisis, written for Advanced Topics in Project Management (COM5451) at Florida State University during the Spring of 2015.

Reference:Deming, W. E. (1991). Out of the Crisis. Cambridge: Massachusetts Institute of Technology.